maritime shipping

Corrosion protection for maritime shipping

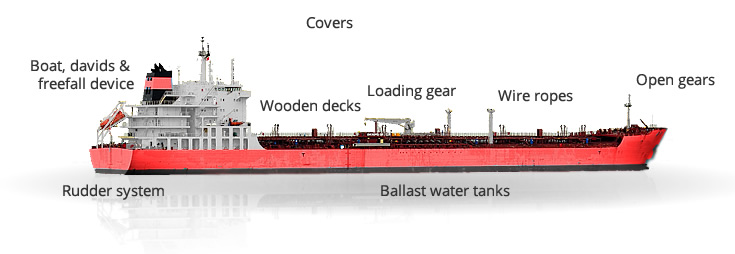

FLUID FILM is the trademark for a group of soft coatings developed for the long-term protection of all metal surfaces against corrosion in marine atmosphere and seawater.

The concept of these advanced soft coatings is based on over 60 years of experience and worldwide recognition of Eureka Chemical Company as a leader in the field of soft corrosion protection.

The combination of proven quality and performance of FLUID FILM products enables the most effective and economical solution to many corrosion problems.

PROFESSIONAL CORROSION PROTECTION

In conventional painting systems, surface preparation by blasting and observance of the dew point during processing is an essential prerequisite for adhesion. Compliance with favourable environmental conditions during the drying phase is also important for trouble-free curing and thus crucial for optimum corrosion protection.

For these measures, a high technical effort is necessary, which is often not feasible, e.g. in the repair of ballast water tanks. Only excellent ventilation over several days, even of the hard-to-reach rear areas, ensures a flawless, dry surface. Removing rust and old paints by blasting is usually impossible.

Fluid FILM soft coatings are the solution to these problems. Years of shipping results show that the solvent-free LANOLIN-based FLUID FILM products are particularly suitable for these applications.

FLUID FILM products also offer a proven and economical solution for many other special requirements.

They have excellent penetration properties in residual rust, adhere to intact used paints, are sliding and highly resistant to all types of water and also adhere to damp substrates (FLUID FILM Liquid AR, FLUID FILM Liquid A, FLUID FILM AS-R and FLUID FILM WR-L).

In coating technology, these products offer further advantages such as:

- thick film processing application

- application by floatation

- solvent-free and yet applicable with conventional airless devices

- No unusual safety measures due to the risk of fire and explosion.

In the technical data sheets you will find information about the individual qualities of FLUID FILM products as well as suggestions about their areas of application.

Our technical service will be glad to provide you with detailed information.

VIDEOS

Dieses Video wird von YouTube bereitgestellt. Mit dem Abspielen dieses Videos akzeptieren Sie die YouTube Datenschutzbestimmungen.

FLUID FILM & PERMA FILM use in the ballast water tank

Dieses Video wird von YouTube bereitgestellt. Mit dem Abspielen dieses Videos akzeptieren Sie die YouTube Datenschutzbestimmungen.

FLUID FILM Interview in the Port Museum of Hamburg (german)

PDF – FLUID FILM in maritime shipping

For a full screen view, click on the diagonal cross.

To download the PDF, click on the 3 dots on the left and then go to “Download”.

PRODUcT overview maritime shipping

FLUID FILM Liquid A

VISCOSITY: low (eg. like olive oil) |

CREEPABILITY: + + + + + |

DURATION: min. 2 years (in closed cavities) |

PROCESSING: with conventional compressed air systems without heating the material or in the flood method

FLUID FILM AS-R

VISCOSITY: low (e.g. like sirup) |

CREEPABILITY: + + + + |

DURRATION: ca. 4 years (in closed cavities) |

PROCESSING: Spray can with additional Feinapplikator

FLUID FILM NAS

VISCOSITY: low-medium (eg. like ketchup) |

CREEPABILITY: + + + |

DURATION: ca. 8 years (in closed cavities) |

PROCESSING: with conventional compressed air systems to heat the material to about 25 ° C or with airless systems

FLUID FILM Liquid AR

VISCOSITY: medium (eg. like honey) |

CREEPABILITY: + + |

DURATION: ca. 15 ears (in closed cavities) |

PROCESSING: with conventional compressed air systems to heat the material to approximately 45 °C or with airless systems

FLUID FILM GEL B

VISCOSITY: high (eg. fat milk) |

CREEPABILITY: + |

DURATION: ca. 20 years (in closed cavities) |

PROCESSING: Airless systems or brush / roller

FLUID FILM WRN-EP

VISCOSITY: very high (eg. like Butter) |

CREEPABILITY: + |

DURATION: ca. 30 years (in closed cavities) |

PROCESSING: Wire rope lubricator or brush / roller / wool glove

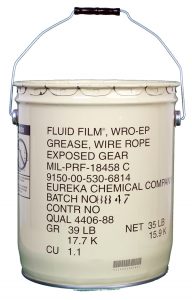

FLUID FILM WRO-EP

FLUID FILM WRO-EP Fluid Film | Industry | Agriculture | Truck | Aerospace | Shipping | Recreational boating | Wind turbines | Winter service VISCOSITY: very high (e.g. ike hard butter)CREEP ABILITY: +PROTECTION PERIOD: approx. 30 Years (in closed cavities)PROCESSING: Wire rope lubricator or brush / roller / wool gloveMILITARY APPROVAL: MIL-G-18458B (SH) FLUID FILM WRO-EP – […]

PERMA FILM englisch

VISKOSITY: low |

Processing: brush, roller, pressure cup gun, airless spraying |

Color: transparent (clear), black, aluminum, buff (ocher)